Food Extrusion Processing

The High Temperature Short Time extrusion process seems simple enough but technology to control all the process parameters and variables of ingredients make it a highly technical manufacturing process. The extrusion process produces minimal waste, with a minimal amount of labor along with increased product throughput. It’s a very efficient and economical way to produce an endless variety of food products like flat breads, cookies, textured vegetable proteins, puffed cereal grains and pasta type products.

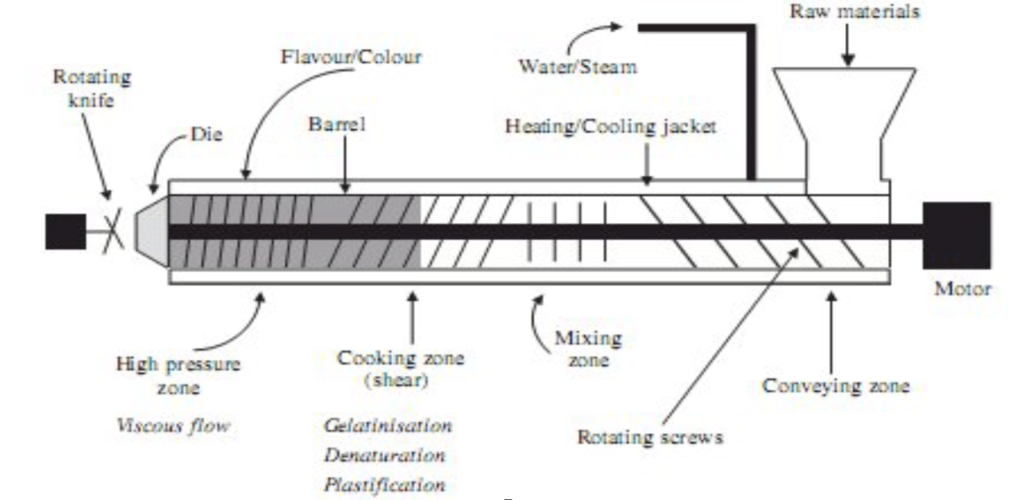

Extruders can be short or long, single screw or twin screw, depending on the product’s processing parameters. The extruder adds liquid and dry ingredients together in the feed section of the barrel. This section mixes ingredients together and continuously builds heat and pressure in the compression barrel where the ingredients start to melt. The heat and pressure is created by the screws building up friction on the barrel sides and screw fins mounted along the shaft. This (HTST) cooking process is controlled by the products feed rate, moisture content, screw speed, barrel temperature, screw and die dimensions, and all factors control the differing cell structures that form.

The final barrel, or metering section, builds pressures between 300 and 1,200 psi and 350 Fahrenheit turning the product into a plasticized and fluid biopolymer and denatured protein. In the final seconds of the last barrel, with product in a semi-molten state, it exits through a die where the extruded and now expanded pieces are cut with a rotating knife.

The most important ingredient needed in extruded foods is starch. It plasticizes under heat and pressure and is the building block of the product. Protein can be added up to a certain point and the more added will decrease expansion resulting in harder texture and irregular shapes. Lipids are added for lubrication in small amounts. Leavening agents can be added for better cell structure. Emulsifiers are commonly used to help protect starch structure during extrusion.

SPI group carries a large assortment of extruded products, including soy, whey and pea protein crisps and textured soy, wheat and pea proteins pieces in various shapes, sizes and protein levels. Please contact your local SPI representative or call our office at 1-800-351-8012 if you’d like to find out how an extruded ingredient can add to the texture and quality of your product.

Information in this blog was obtained from the Extrusion Course put on by Washington State University and instructed by Girish Ganjyal.

Single Screw Extruder

Recent Comments